Our Manufacturing Process

At Adipoluxe, our process is built around three promises: clinical-grade precision, consistent quality, and brand-ready customization. We manufacture liposuction cannulas, dental instruments, and single-use dental instruments with a workflow designed to reduce errors, protect cleanliness, and help our partners build strong product lines in their markets.

1) Discovery: understanding your product and your brand

Every order starts with clarity. We don’t only ask “what instrument do you need?”—we also ask how you want it positioned. Are you building a premium surgical line, a value-focused single-use range, or a complete catalog for distribution?

For liposuction cannulas, we confirm details such as diameter, length, handle design, port pattern, tip type, tubing stiffness, and performance feel. For dental instruments, we confirm the exact working-end design, grip texture, balance, and intended procedures.

At the same time, we map your brand requirements: preferred finish style, packaging look, labeling language, logo placement, and the type of customers you target (hospitals, clinics, distributors, or e-commerce).

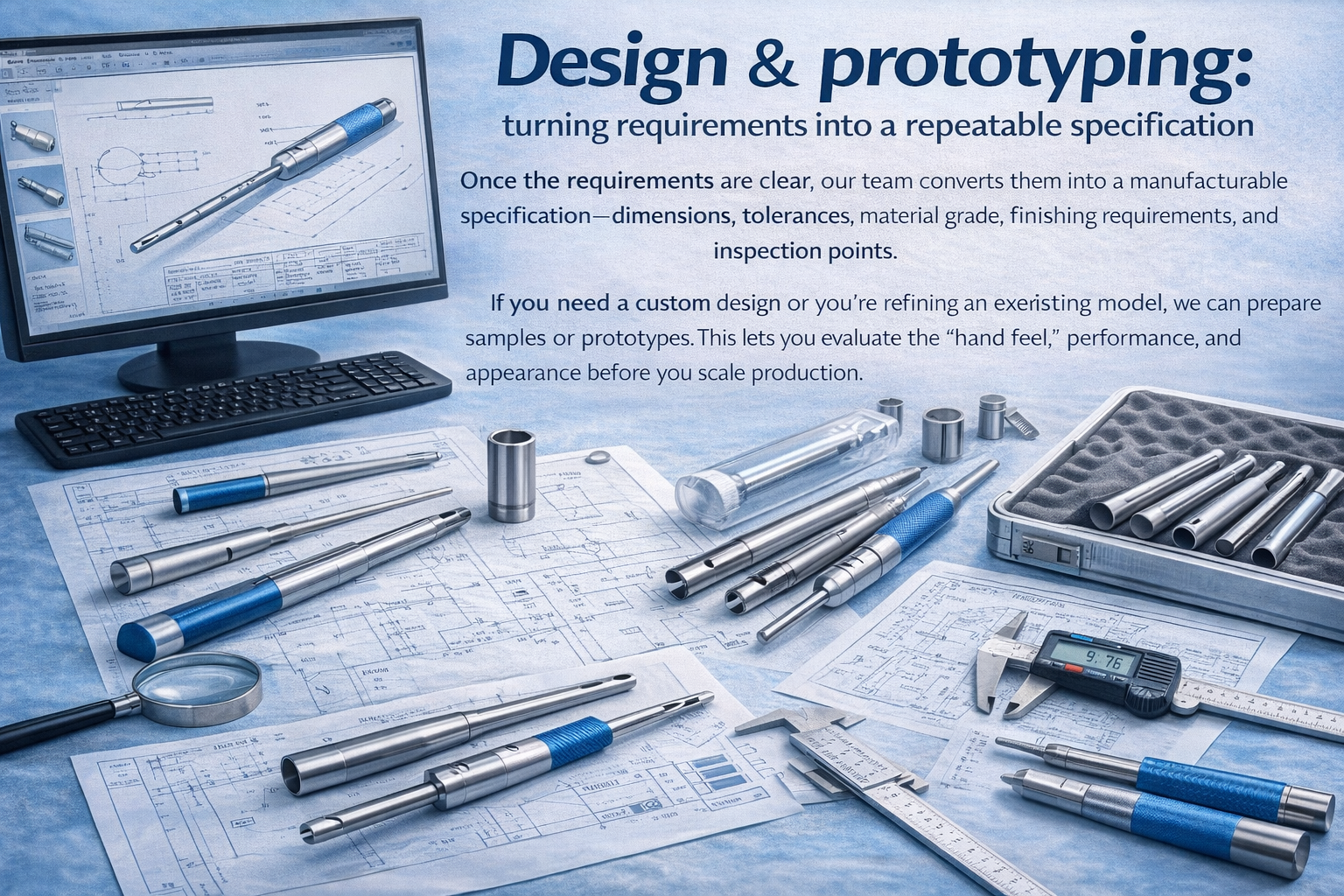

2) Design & prototyping: turning requirements into a repeatable specification

Once the requirements are clear, our team converts them into a manufacturable specification—dimensions, tolerances, material grade, finishing requirements, and inspection points.

If you need a custom design or you’re refining an existing model, we can prepare samples or prototypes. This lets you evaluate the “hand feel,” performance, and appearance before you scale production. For single-use instruments, we also define packaging format early because it affects the entire production flow.

3) Material selection: performance, safety, and consistency

Instrument reliability starts with the right materials. We choose medical-grade stainless steel and suitable polymers based on the instrument’s application, corrosion resistance, durability, and surface finish needs.

Reusable instruments prioritize long-term strength, clean finishing, and stable performance. Single-use items prioritize controlled manufacturing, safe handling, and consistent output—so every unit behaves the same in the clinic.

4) Precision manufacturing: controlled fabrication for dependable results

Our manufacturing stage is designed for repeatability. Liposuction cannulas require careful control of tube geometry, port edges, tip finishing, and handle alignment. Dental instruments require accurate working ends, solid joints (where applicable), and ergonomic shaping that feels stable in the clinician’s hand.

We treat these products as medical tools from the first step—not generic metal parts—because the smallest inconsistency can affect clinical usability and customer trust.

5) Finishing & refinement: where quality becomes visible

Finishing is where instruments become “Adipoluxe-grade.” Depending on your product and positioning, we apply finishes such as polished, satin, or matte textures. We refine edges and tips, improve grip patterns, and ensure surfaces look consistent across batches.

This stage is also important for brand identity—many buyers judge quality immediately by visual uniformity, touch, and overall presentation.

6) Cleaning & controlled handling: protecting cleanliness and surface integrity

After manufacturing and finishing, products go through thorough cleaning processes to remove residues and protect the final finish. Controlled handling reduces surface damage and keeps instruments presentation-ready. Where required, we apply material-appropriate treatments (such as passivation methods suitable for stainless steel) to support corrosion resistance and long-term stability.

7) Quality inspection: checks at every stage, not only at the end

Quality is built into the workflow. We conduct in-process and final checks using defined acceptance criteria. This includes dimensional verification, surface inspection, alignment checks, and functional evaluation where needed. Sampling and batch-level verification reduce variation and help maintain consistent results over repeat orders.

8) Branding, Customization and Private labeling

This is where Adipoluxe supports your growth beyond manufacturing. We offer customization options that help you build a recognizable product line, including:

Logo/brand marking on instruments (as applicable by product type)

Custom finishes aligned with your premium or standard product tier

Custom packaging and labeling to match your brand style

Model naming, SKU structure, and catalog consistency support

Bulk branding for distributors (multi-variant packaging, region-specific labels)

Our goal is simple: when your customer receives the product, it should look and feel like a strong, consistent brand, not just a generic item.

9) Packaging, Protection and Single-Use readiness

We package instruments to protect working ends, tips, and surface finish during shipping. For single-use dental instruments, we support packaging formats suitable for professional presentation and distribution. Label layout, barcodes, and carton branding can be aligned with your market needs. If you are building a full single-use line, we also help you standardize packaging across multiple SKUs for a clean retail or distributor-ready catalog.

10) Long-term partnership: repeatability, scaling, and brand building

Adipoluxe is built for long-term collaboration. We maintain batch identification practices, production records, and repeat-order consistency so you can scale confidently. As your business grows, we can support new product development, improvements, and line expansion—helping you strengthen your position in surgical and dental markets.

From precision manufacturing to brand-ready customization, Adipoluxe delivers instruments you can confidently sell—and your customers can confidently use.